About Us

Two decades of furniture.

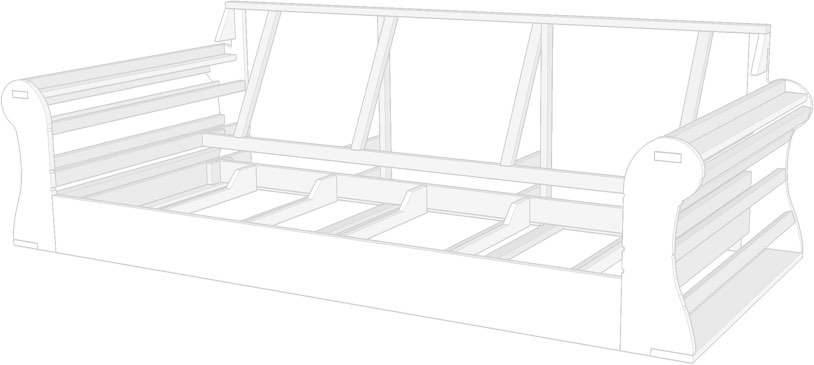

Industrial Timber, Inc. was established in 1999, founded by Mike Ruch, who retired 2019. We are headquartered in Charlotte, North Carolina, where our central office is complemented by a state-of-the-art Innovation Center. The center is used for our extensive R&D efforts as well as testing. It also serves as a workshop for manufacturers to sit with our team and use our technology and know-how to innovate and improve their frame design in real time. Prototype frames are costed to reveal any savings and put into production at the Innovation Center and tested for quality. Industrial Timber is proud to be an ANAB-accredited conformity assessment body. ISO/IEC 17025 Calibration and Testing Laboratory.

“Industrial Timber is in the business of evolving our customers’ vertical milling operations. To do so, we must study every aspect of their costs, from the raw material purchase, to the yields, labor, throughput, footprint, technology, and all the way to packaging and assembly, finding ways to reduce costs and improve efficiency.“

-

Expertise

The IT management team’s reputation, innovative and lean manufacturing platform, R&D capabilities, and our talented, experienced craftsmen work together to create a high-performing, vertically-integrated machine. Unlike some of our competitors who focus on throughput regardless of yield, IT leverages our ability to optimize yield while ensuring all aspects of the process are critically challenged to consistently ensure they are best of breed. The goal is to manufacture a superior product at a cost that is significantly lower than other suppliers, and even lower than what a vertically-integrated upholsterer can produce.

Approach

Industrial Timber’s core philosophy, execution and platform is formed around innovation and evolving the traditional manufacturing premises of wood furniture frame production. This core value proposition has been essential in revolutionizing an industry that has historically been dotted with tiny producers, none able to bring economies of scale to the table in a way that can truly impact a customer’s bottom line. Our state-of-the-art Innovation Center is proof of our committment to leading and advancing the industry.

Proudly crafting more

than 100,000 frames each week.

Critical to that scale and efficiency is IT’s strategic investment in our system of five mill facilities that complement and support each other. These innovative Mini Mills, compact frame operations are either near or inside our customers’ facilities and deliver frames on a just-in-time basis, greatly reducing freight and storage expenses. Three important objectives that our mills fulfill:

Sourcing and processing the highest quality wood products domestically and internationally. (Although IT is a vertically-integrated frame fabricator now, we actually got our start as a lumber wholesaler.)

Employing and training highly technical R&D professionals who design and engineer superior ready-to-assemble wooden furniture frames at a lower cost while at the same time providing customers with superior products.

Offering proprietary logistics and mission-critical frame components on a just-in-time basis to upholsters directly to the assembly line floor.

WE INNOVATE EVERYWHERE WE CAN

Learn MoreCool tech, meaningful job, great industry—join us

IT is at the forefront of an effort to strengthen and preserve the greatness of American furniture by bringing it into the 21st Century through smart processes, great design and powerful technology. If you’re ambitious, we want to hear from you.

View Careers