Engineering a better frame for less is the core of what we do.

Industrial Timber has been helping companies who demand excellence to produce high quality products at industry leading price points since 1999. Founded in forestry, Industrial Timber has grown from a raw material supplier to become the nation’s largest independent furniture frame manufacturer and supplier of custom wood-based solutions. Building a better product for less is the core of what we do. Partnering with a wide variety of industries, from industrial packaging, to furniture frames and beyond we produce eco-friendly solutions that help our customers to increase margin, decrease assembly time, and reduce inventory levels to free up capital that can be used to grow other areas of their business.

*PLEASE NOTE: It has come to our attention that visitors are experiencing issues with the Contact Form at the bottom of the page. Please bear with us while we resolve this issue and use the “Schedule Time With Us” button on the bottom right of the screen to connect with a team member or call one of the numbers listed below (more contact info can be found on our Contact Us page)

Sales: (804) 986-4852

Charlotte HQ: (704) 919-1215

Industrial Timber is

The Smart Play.

We bring tech-centric innovation to your framing operation to make you smarter, faster, and leaner. Our customers realize cost reductions of 10% to 30%, directly impacting their bottom line.

Our ValueDriving costs down—and quality up.

Not only can we contribute to your bottom line through cost savings, we can also improve quality, adding to your brand’s value. Here’s how we do it:

MATERIALS SOURCING

With our scale and global relationships, IT procures high quality dimensional lumber and engineered wood at an industry-leading price point.

MATERIALS LOGISTICS

Our proprietary just-in-time Buggy System provides a simple “erector-set” model ensuring all core frame components are in a predetermined space. This ensures mission-critical components are right at your team’s fingertips exactly when they need them without the hassle of a forklift.

MATERIALS OPTIMIZATION

With smarter process and technology, we can achieve an overall materials yield of 78% versus the industry average of just 50% to 60%.

RESEARCH & DEVELOPMENT

Our R&D team has helped get our plywood and OSB panel yield to an astounding 98+% by using special software to optimize digital “nests” before CNC routing.

EFFICIENT ASSEMBLY

Our in-house team of expert engineers develops highly efficient “nests” to ensure your parts are cut accurately and produce little to no waste. These parts are packaged specifically for each customer to ensure they best fit into the current work stream of your operation.

-

01 MATERIALS SOURCING

-

02 MATERIALS LOGISTICS

-

03 MATERIALS OPTIMIZATION

-

04 RESEARCH & DEVELOPMENT

-

05 EFFICIENT ASSEMBLY

WE INNOVATE EVERYWHERE WE CAN

Learn MoreCool tech, meaningful job, great industry—join us

IT is at the forefront of an effort to strengthen and preserve the greatness of American furniture by bringing it into the 21st Century through smart processes, great design and powerful technology. If you’re ambitious, we want to hear from you.

View CareersProudly crafting more than 100,000 frames each week.

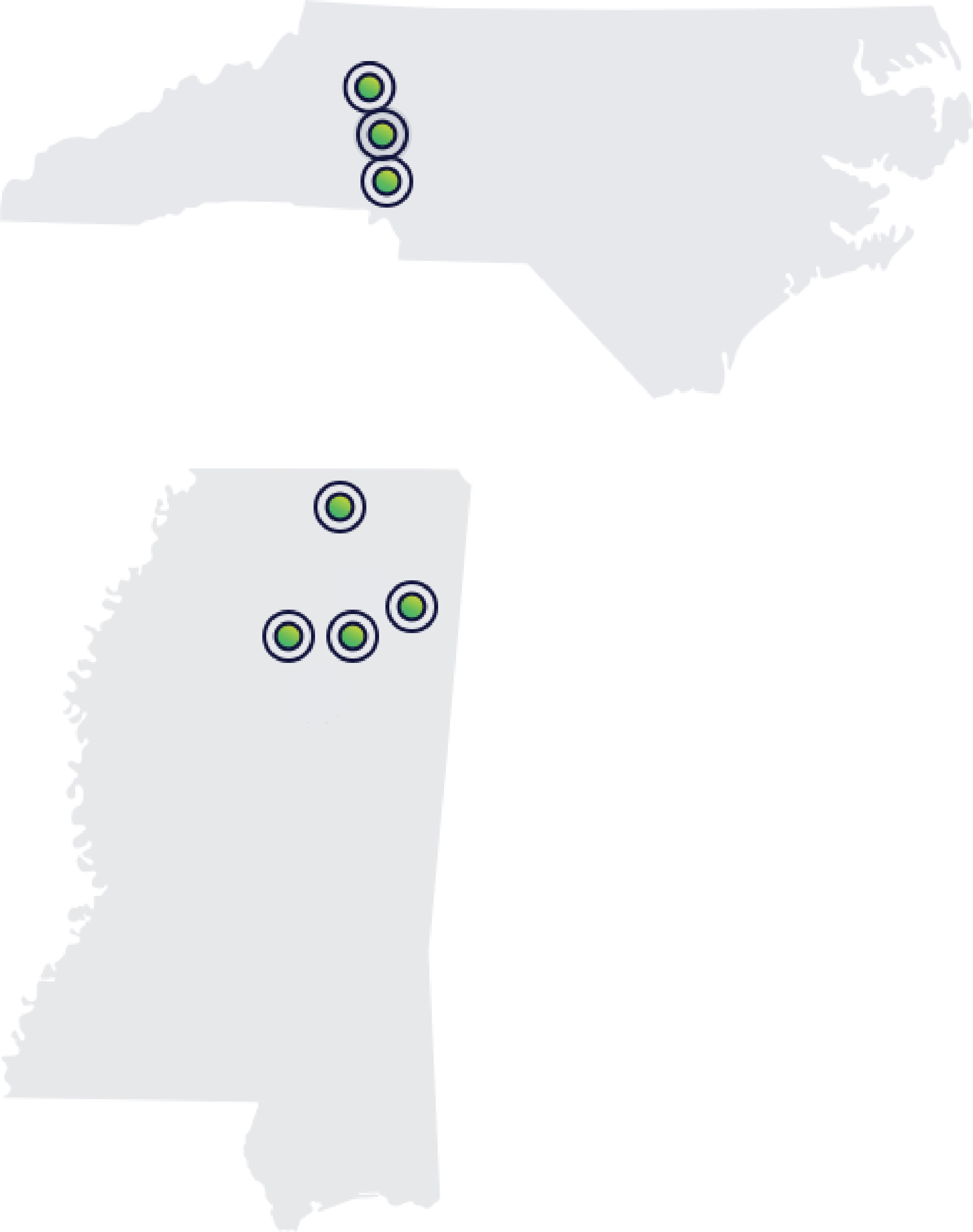

IT has strategically invested in a system of mill facilities that complement and support each other in the name of efficiency. This includes innovative Mini Mills: compact frame operations that are either near or inside our customers’ facilities and deliver frames on a just-in-time basis, greatly reducing freight and storage expenses.

OUR GEOGRAPHIC FOOTPRINT

- NORTH CAROLINA LOCATIONS

- *HQ* CHARLOTTE, NC

- TAYLORSVILLE, NC

- CLAREMONT, NC

- MISSISSIPPI LOCATIONS

- RIPLEY, MS

- PONTOTOC, MS

- TUPELO, MS

- MANTACHIE, MS